An electronic duplicate of a real system, asset, or setting that is intended to replicate real-world circumstances in real time is called a digital twin.

Digital twins that are driven by artificial intelligence (AI) can forecast results, optimize processes, and offer actionable insights like never before.

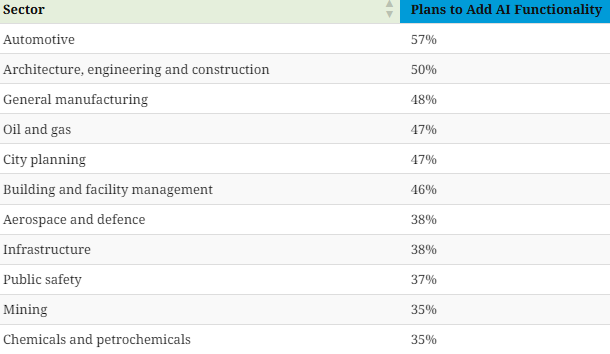

A 660 C-level executives from 11 different countries participated in the Hexagon survey, which we used to create this graphic, which illustrates which industries intend to integrate AI capabilities into digital twins.

The Automotive Industry Leads

According to Hexagon’s most recent report, the industries with the highest planned usage percentages for AI-driven digital twin adoption are highlighted:

The automotive sector is the most adopting, with 57% using the technology to enhance safety testing through simulations and optimize production lines.

Digital twins enable real-time project monitoring in the 50 percent adoption rate of the architecture, engineering, and construction sectors, which improves resource allocation and reduces delays.

General manufacturing, which uses AI-enhanced digital twins to optimize equipment efficiency, minimize costly errors, and streamline operations—especially in high-stakes processes—follows closely behind at 48%.